Infrared Thermography Inspection Services: A Critical Tool for Modern Industry

Infrared Thermography Inspection Services: A Critical Tool for Modern Industry

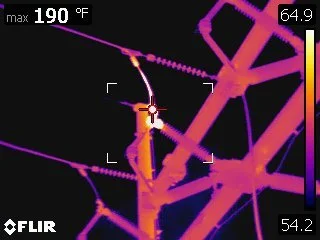

Electrical systems are the backbone of industrial operations, and when they fail, the consequences can be severe unexpected downtime, equipment damage, productivity loss, or even safety hazards. Infrared thermography inspection services help prevent these issues by detecting thermal anomalies long before they escalate into major problems.

At Invizions, our certified thermographers use state-of-the-art infrared cameras to evaluate temperature patterns in electrical systems, mechanical components, and high-voltage equipment. These heat signatures often reveal hidden issues like loose connections, failing transformers, overloaded circuits, worn insulation, and imbalance conditions that would otherwise go unnoticed.

Why Infrared Thermography is Essential

Infrared inspections offer several advantages for industrial facilities:

Non-invasive evaluation with no operational interruption

Early detection of electrical degradation or hazardous hotspots

Improved maintenance planning through accurate temperature data

Increased uptime and equipment longevity

Thermography contributes directly to predictive maintenance strategies by identifying problems proactively rather than reactively.

Industries We Serve

Invizions provides infrared thermography inspection services throughout:

California – large-scale solar fields, refineries, agriculture processing, tech manufacturing

Texas – petrochemical plants, heavy industry, energy production, oil and gas operations

Ohio – industrial manufacturing, hospitals, transportation facilities, education campuses

Each state has distinct electrical infrastructure challenges, and our team is trained to understand the thermal patterns associated with different environments, industries, and regulatory expectations.

Maximizing Operational Reliability

With more than 20 years of experience in nationwide predictive maintenance, Invizions helps organizations stay ahead of electrical failures. Our detailed reports include thermal images, temperature trends, severity classifications, and corrective recommendations, giving maintenance teams the clarity they need to act quickly. Thermography is not just a scan, it’s a strategic investment in safer, smarter, and more reliable operations.